Aft Peak Tank with Stern frame Arrangement :-

The construction of Aft end structure also differs from the rest of ship. Here, propeller shaft passes through aft peak bulkhead and Rudder and propeller needs to be supported with suitable stern frame.

Earlier cruise stern ( rounded type ) was favoured stern type in use for ocean going vessels. Of late, Transom stern is used, as it provides more deck areas and is simpler in construction. As stern is also subjected to large slamming ( pounding ) forces, adequate strengthening is required.

Aft Peak Tank : This compartment extends from after peak bulkhead to the stern frame and aft end of the ship. In this tank also, deep solid floors are fitted at every frame space a/w a heavy centre line girder is fitted right aft as additional strength is required to support the stern which overhangs here and may be subjected to large slamming forces. Double bottom is discontinued here. The floor to which rudder post is fitted is heavier and extra strong and it is called “ Transom Floor ”. This floor is designed to support the overhanging mass and framework of the stern.

Aft of transom floor – a heavy centreline girder and side girders are fitted. Transverse solid plate floors are fitted at every frame from aft peak bulkhead to the steering flat. In Aft peak also similar panting arrangement ( panting stringers ) are provided with spacing of 2.5m apart. A centreline wash bulkhead is provided.

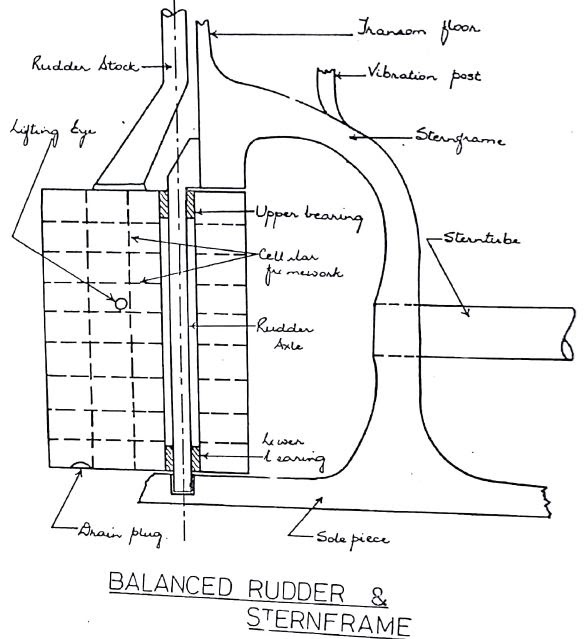

The stern tube which houses the propeller shaft extends from aft peak bulkhead to stern frame. In the aft portion a rudder trunk is provided through which rudder stock passes.

This tank is used for water ballast or sometimes as Fresh water tank.

Sternframes : This is an important structure found in the aft part of the ship. To prevent serious vibration at the after end, there must be adequate clearances between the propeller and the stern frame which decides the size of stern frame. The stern frame supports the propeller shaft, propeller and the rudder. The bottom part extends out to form the "Sole piece" which supports bottom bearing of rudder and upper end supports the upper bearing of the rudder. It also streamlines the stern so that eddies are not created and hull resistance does not increase. During drydock, vessel should not have Exccesive trim – as Stern frame might get damaged as Stern frame takes to the block first. It can be cast in foundry, but now a days, it is fabricated in shipyard only where ship is made – as it turns out to be cheaper.

.webp)

0 Comments