SHIP CONSTRUCTION

STRESSES EXPERIENCED BY A SHIP :-

General : A ship is subjected to a number of forces causing stress and strain on its structure during its working life which can cause damage to its form or its structure. Hence, Due counter measures are taken at design stage and during construction so that vessel can withstand such forces in both static ( in port ) and dynamic ( in motion at sea ) conditions.

What is Stress and Strain ?

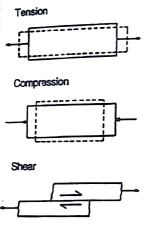

Stress is a load or force acting per unit area ( in kg/mm2 ). They are maily three types –

1- Tensile Stress : Force causing tension to increase the length ( elongation force ). Now a days, Tensile steel is used in ship building to counter this which also reduces weight of vessel, hence more cargo.

2- Compression : Forces acting in such a direction as to decrease the length.

Shear : the effect of two forces acting in opposite directions and along parallel lines so as to cause a tearing effect or to cause various parts of a section to slide over one another.

Strain is the distortion in a material due to stress.

Mechanical properties of metals :

Elasticity : when the material goes back to its form, that’s elastic deformation.

Plasticity : The ease with which a metal can be bent or moulded into a given shape ( irreversible change).

Britleness : The opposite of Plasticity, lack of elasticity.

Malleability : The property of a metal of becoming permanently flattened or stretched such as Gold.

Ductility : Ability to be drawn out lengthwise, the amount of the extension measures the ductility.

Hardness : The property of a metal to resist wear and tear and abrasion.

Fatigue : A metal subjected to continually applied loads may eventually fail from fatigue.

Forces to Which a Ship is subjected :

A ship at sea is subjected to a number of forces causing the structure to distort. They may be divided into two categories, as follows :

- Static forces : Two forces act on the vessel when they are in still water as well as when in motion. They are the force of gravity acting downwards ( due to weight of ship and its cargo ) and the force of buoyancy acting upwards ( due to upward thrust). When they are in equilibirium, vessel is said to be at rest.

Rolling, pitching, Heaving, Surging, Swaying and yawing.

- Dynamic forces : These forces act on the ship while ship is in motion . While underway, Vessel is also subjected to six degree of motion namely, Rolling, pitching, Heaving, Surging, Swaying and yawing. When these motions are large then very large forces may be generated. Though, they are local in nature e.g pounding forward, but they cause structure to vibrate and transmit the stresses to other parts of the structure.

These forces produce two type of stresses in ship’s structure :

1- Global stresses ( namely Longitudinal stresses in still water or in seaway causing hog and sag + shearing stresses ) – affecting the whole ship.

2- Local stresses – those affecting a particular part of the ship.

Water pressure : When vessel is partly submerged, water pressure acts at its bottom as well as on its sides. Pressure increases with depth. Hence, bottom part of the ship must be extra strengthened to counter this.

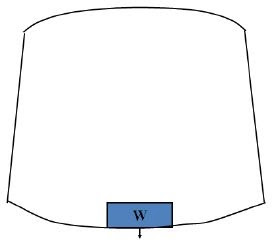

Localised loading : Often in case of loading, High density cargo, load may be placed in only one hold. This will cause the force of gravity exceed the force of buoyancy in that local region. The bottom structure will tend to sag outward, as in the figure.

What is Hog and Sag ?

Hog : When weights are placed at more at the ends as compared to amidship, the force of buoyancy amidship will exceed force of gravity amidship – causing, vessel to be hogged ( midship draft less than fore and aft draft ) . As a result, the deck of vessel will be under tension and bottom plating under compression.

Sag : When weights are placed more amidship as compared to, at the ends., the force of buoyancy amidship will be less than the force of gravity amidship – causing, vessel to be Sagged ( midship draft more than fore and aft draft ) . As a result, the deck of vessel will be under compression and bottom plating under tension.

Panting : When vessel moves through water, the waves moving past the bow, it causes bow plating to move in and out in a fashion as if a person is breathing heavily ) called panting. Hence, special strengthening is required in the forepeak region .

Pounding : When a vessel is pitching heavily, there will be times when the bow is completely lifted out of water and slammed back into the water causing tremendous stresses on the forwards part of the vessel. That’s why forward 0.25 L of vessel is extra strengthened as per class rules.

Racking : When vessel is moving through cross seas, i.e, with the sea crossing from port to starboard or vice-versa.when crest is hitting one side of the ship, it tends to get deformed away from the crest, towards the trough. This process alternates and is called Racking forces.

Torsion : When vessel is riding on a wave at an angle, it will be subjected to a twisting moment ( torque ) and the structure in under torsion. The greatest effect occurs with decks having large openings.

- Local forces : This type of stresses are experienced in certain part of the ships only.

Vibrations : experienced mainly in areas of Machinery spaces, pump room and propeller etc. adequately strengthened to dissipate the vibration and avoid structural damage.

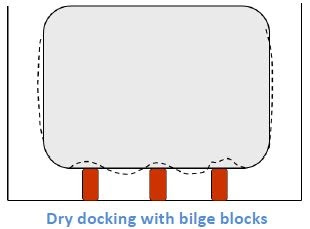

Drydocking : When vessel is in drydock, the entire bottom sits on three rows of concrete blocks causing unsupported portions to sag.

In way of Hatch Comming : When there is sudden discontinuity of structure, they stresses build up in that region and there are chances of crack developing there. Hence, opening’s like hatch coaming are rounded at the corners to avoid locked in stresses and extra strengthening is provided to compensate for loss of strength due to discontinuity in structure.

At the forward of Super structure : The superstructure causes abrupt end to deck plating, hence extra strengthening is provided in this region.

.webp)

0 Comments